Mixer Settler equipment Work Principle

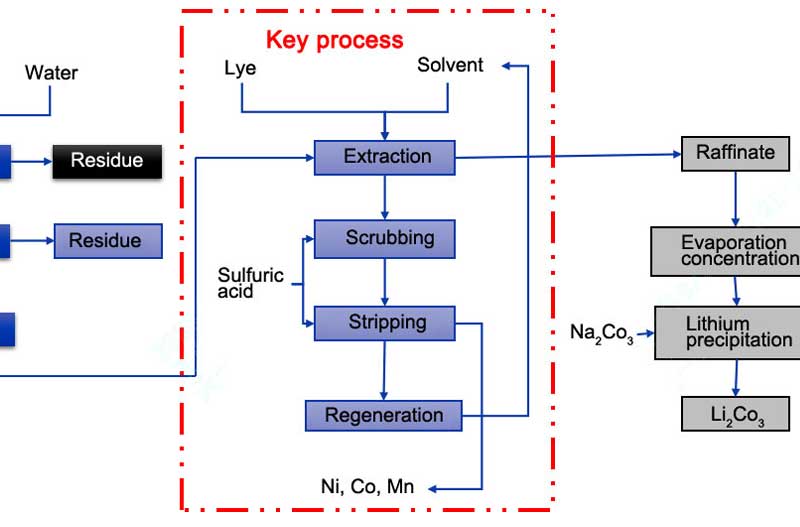

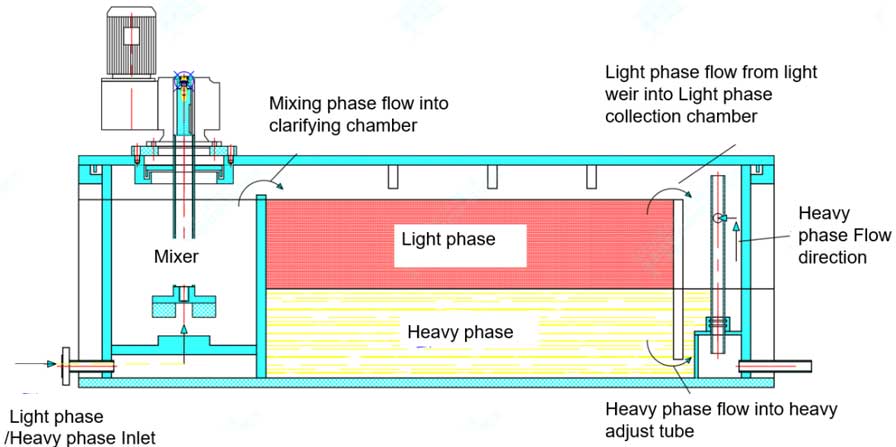

The specific working process of the Mixer Settler (mixing and clarifying Settler) is that the feed liquid and extraction agent enter the mixing chamber through their respective feed ports by the feed pump, and the high-speed rotating stirrer causes the feed liquid and extraction agent to mix and transfer, and then Entering the clarification chamber through the overflow baffle, the light and heavy phases are separated under the action of gravity. The separated light and heavy phases enter different outlets respectively to complete an extraction process. In actual production, the extraction tank is generally a multi-stage series connection, including multiple sections such as extraction section, stripping section, washing section and regeneration section. The specific configuration should be based on the production process.

Mixer Settler Mixer

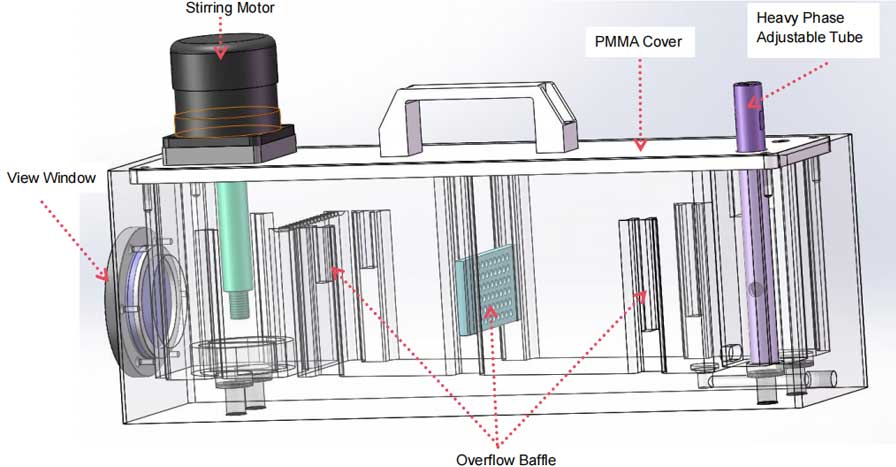

A mixing chamber where a mechanical agitator brings in intimate contact the feed solution and the solvent to carry out the transfer of solute(s). The mechanical agitator is equipped with a motor which drives a mixing and pumping turbine. This turbine draws the two phases from the settlers of the adjacent stages, mixes them, and transfers this emulsion to the associated settler. The mixer may consists of one or multiple stages of mixing tanks. laboratory mixers and industrial scale mixers may consist of a single mixing stage or Multistage mixer stages where each stage performs a combined pumping and mixing action.

Mixer Settler Settler

A settling chamber where the two phases separate by static decantation. Coalescence plates facilitate the separation of the emulsion into two phases (heavy and light). The two phases then pass to continuous stages by overflowing the light phase and heavy phase weirs. The height of the heavy phase weir can be adjusted in order to position the heavy/light interphase in the settling chamber based on the density of each one of the phases. The settler is a calm pool downstream of the mixer where the liquids are allowed to separate by gravity. The liquids are then removed separately from the end of the mixer.

Mixer settler Technical Specification

| Model | Mixing Volume | Settler Volume | Material |

| CC-0.3 | 0.3L | 1:3 OR 1:4 | PP(Overall forming),PTFE (Overall forming),PVDF (Overall forming),Transparent PVC, Stainless Steel .......... |

| CC-0.4 | 0.4L | 1:3 OR 1:4 | |

| CC-0.5 | 0.5L | 1:3 OR 1:4 | |

| CC-1 | 1L | 1:3 OR 1:4 | |

| CC-2 | 2L | 1:3 OR 1:4 | |

| CC-5 | 5L | 1:3 OR 1:4 |

Customized Large Industrial mode according to technical process requirements