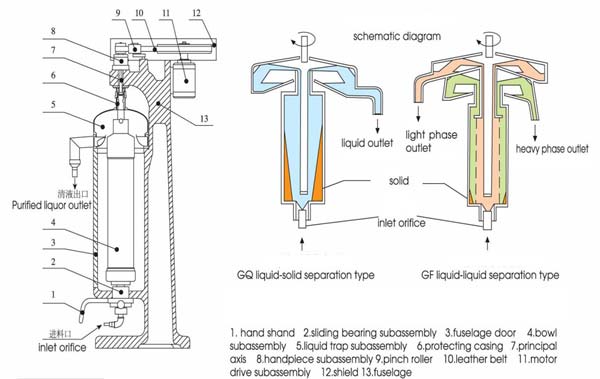

Tubular Centrifuge Work Principle

The separation principle of a tube centrifuge is that the material to be separated is input into the centrifuge. Under the action of the centrifugal force field, the material utilizes the centrifugal force generated by the centrifuge to effectively separate substances with different densities.

Tubular Centrifuge Technical Specification

1. Inner diameter of drum: 75mm

2. Speed: 20000 rpm.

3. Centrifugal force: 16700xg

4. Solid phase volume of the rotor; 2 liters.

5. Water flow capacity: 0.15T/h. 6 Actual production capacity: 5-80kg/h (related to material concentration, viscosity, solid content, and separation requirements).

7. Power supply: 380V 50Hz

8. Total power consumption: 1.5kw

9. Inlet diameter; 14mm

10. Discharge port diameter; 30mm

11. Material: The entire machine and the parts in contact with the material are all made of SUS 304 stainless steel material.

12. Overall weight; 260 kg

13. Bearings; FAG bearings imported from Germany.

14. Motor; Equipped with Swiss ABB brand motor and variable frequency speed control box, the speed can be adjusted from 0 to 20000 rpm.

15. Boundary dimensions: (length x width x height) 650 x 450 x 1200 (mm).

16. Power supply; AC380V 50Hz (motor power 1.5kw).

If you want to learn more about our Tubular Centrifuge, Leave Message Online