High mixing efficiency and good extraction effect

According to the requirements of different material systems, mixed structures can be flexibly combined to achieve efficient extraction.

Small amplification effect

Centrifugal force is used for separation and precise mixing, with process strengthening equipment and minimal amplification effect.

Small footprint

Compact structure, saving footprint and operating space.

Good two-phase separation effect

Using centrifugal force to separate the aqueous and organic phases, separation is fast and stable, avoiding human interference.

Low online liquid holding capacity

Internal liquid holding capacity is small, such as the liquid holding capacity of the 6m ³/h treatment equipment can be 35L.

Saving

Low power, fully enclosed, efficient, environmentally friendly and energy-saving equipment.

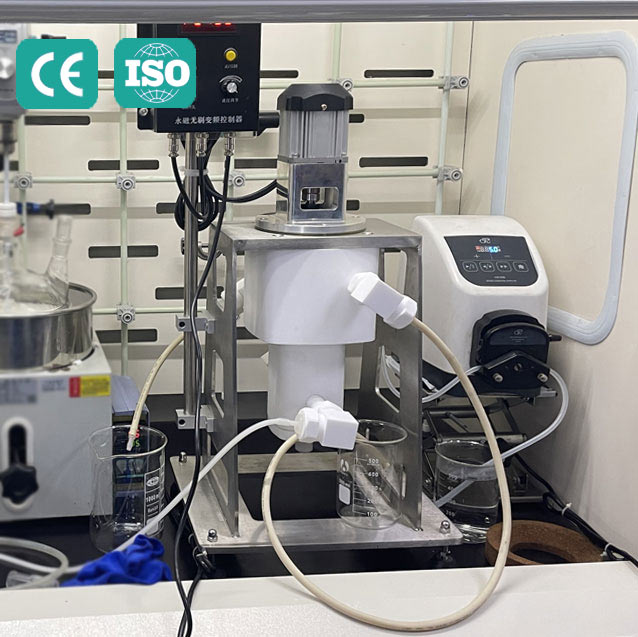

Laboratory centrifugal extractor Work Principle

1) Solvent extraction equipment Mixed mass transfer process

The two-phase solutions enter into the mixing area of inside the shell from the two phase inlet ,which in a certain proportion to make the two phases mix

and disperse quickly and complete the mixing mass transfer process.

2)Solvent extraction equipment Two phase separation process

The mixed liquid enters the drum under the action of the vortex disc or feeder. Under the action of centrifugal force, the heavy phase liquid gradually moves away

from the center of the drum and towards the drum wall in the upward flow process; The light phase liquid with low density gradually moves away from the drum

wall and towards the center. The clarified two-phase liquid finally enters the collection chamber through their respective weir plates and flows out from the light

phase outlet to complete the two-phase separation process.

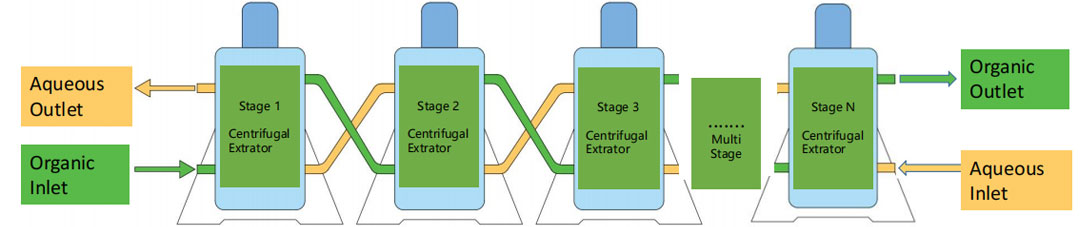

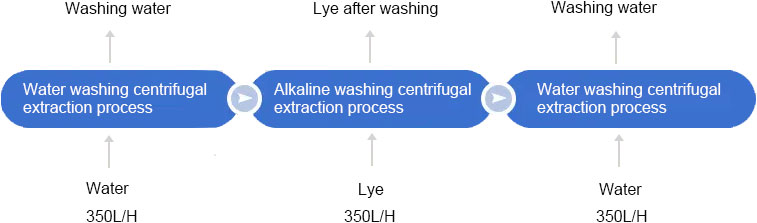

Solvent extraction equipment Schematic diagram of the extraction process

Laboratory centrifugal extractor Technical Specification

| Model | Rotor Drum | Extractor | |||

| Dia(mm) | Rotor Speed(rpm) | Capacity Phase Flux(L/h) | Motor Power(kw) | Dimension(mm) | |

| LXC-20 | 20 | 6000 | 0.3-6 | 0.09 | 240×240×750 |

| LXC-40 | 40 | 3000 | 1.2-50 | 0.25 | 420×380×890 |

| LXC-50 | 50 | 3000 | 1.2-50 | 0.5 | 420×380×890 |

If you want to learn more about our Laboratory centrifugal extractor, Leave Message Online