Continuous chemical equipment

provider

provider

In the chemical and pharmaceutical industry, the production of penicillin is a common operating unit, and the solvent extraction method has a significant effect in the extraction process. The solvent extraction method uses suitable extractants to extract and separate penicillin from the feed liquid, with high extraction efficiency and large processing capacity.

For the extraction of penicillin, ethyl acetate is selected as the extractant, solvent extraction method is selected as the process, and common equipment selection includes liquid liquid centrifugal extractors, liquid-liquid mixer-settler, extraction towers, reaction kettles, etc. The extraction rate and processing capacity of penicillin vary among different extraction equipment.

Recently, a customer inquired about penicillin extraction equipment. The company previously used extraction towers for penicillin extraction, but during the operation, there were phenomena such as low processing capacity, entrainment, and flooding. In response to these phenomena, the customer wants to replace the equipment. I hope our company can provide corresponding equipment and processes.

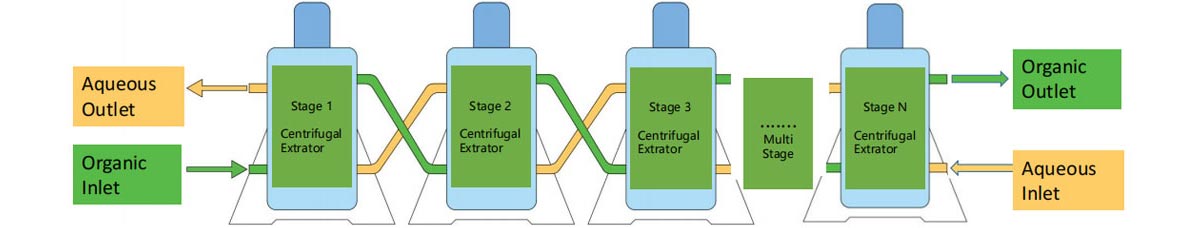

In response to the customer's issue, our company has selected liquid liquid centrifugal extractor equipment and ethyl acetate as the extractant. The specific process is to inject the feed liquid and extractant into a centrifugal extractor through different feed ports according to a certain ratio. The feed liquid and extractant are quickly mixed and transferred through the centrifugal force of the centrifugal extractor, and then the extractant containing organic phase is separated from the feed liquid through centrifugal shear force, and discharged from the body through different discharge ports.

Focus on being Continuous chemical equipment

provider.

If you want to learn more about our centrifugal extractor, mixer settler, Contact us Now