Continuous chemical equipment

provider

provider

Rare earth elements are essential for use in modern technology and are key components of most electronic products. Despite the importance of rare earth elements, only about 1% of them are recovered from the final product, with the rest turned into waste.

There have been recent challenges in developing efficient REE recovery processes. This article will discuss different methods of recycling REEs and show that it is possible to recover REEs from waste to make permanent magnets.

Application of rare earth elements

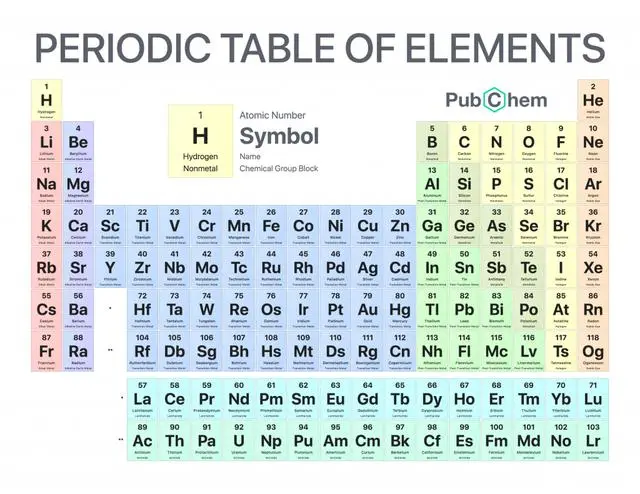

Rare earth elements, also known as rare earth metals, are a group of 17 different elements that each share a characteristically similar physical characteristic: silvery-white soft heavy metals. Scandium and yttrium are also rare earth elements because they occur in the same deposits as most lanthanides and exhibit similar chemical properties but differ electronically and magnetically. Each rare earth element has various applications and uses.

Here are some of their applications:

Scandium alloys are used in the manufacture of aerospace components and radioactive heat tracers in oil refineries.

Yttrium is used in the manufacture of camera lenses and refracting telescope lenses.

Promethium is used to make car batteries.

Samarium is used to make lasers, neutron capture and control rods for nuclear reactors.

Other applications of rare earth elements include making hard drives, magnets, X-ray machines, metal halide lamps, fiber optic technology, LED light bulbs, and more.

Waste that may contain rare earth elements

Rare earth elements are emerging pollutants that pose risks to the environment due to their increasing use in different technological applications. E-waste remains an important source of REE pollution. This is because e-waste contains high concentrations of rare earth elements, which are often disposed of in unsafe ways and are harmful to the environment.

Recycling of rare earth elements

Rare earth metals are very critical components present in different consumer products such as permanent magnets, electric vehicles, smartphones, etc. It occurs naturally in ores in a mixture that must be purified before use. Rare earth elements are expensive to mine, so it is cheaper to recycle rare earth elements that have been processed into materials.

Despite their ability to be reused, products containing rare earths are used only once and discarded. Recycling rare earth elements will provide manufacturers with a steady supply of rare earth metals while reducing waste and the significant environmental burden it creates. Electronic waste is a major source of rare earth elements.

Recent advances in recycling technology have made it more feasible to extract rare earth elements from these materials. Japan, for example, has a number of recycling plants in operation, and an estimated 300,000 tons of rare earth metals are stored in unused electronics.

Also, in France, efforts are underway to build two factories that will produce 200 tons of rare earth metals per year from used fluorescent lamps, batteries and magnets. In addition, coal and by-products are potential sources of key elements, including rare earth elements, which are estimated to yield about 50 million tonnes of rare earth elements.

RECOVERY METHOD OF RARE EARTH ELEMENTS

Developing effective and economical strategies for REE recovery depends on different factors, including commodity prices, deposit size, disposal costs and potential hazards.

The methods used by most developed countries to recover rare earth elements from waste electronic products are:

The gadget is chopped and ground into a powder form from which the basic ingredients, the rare earth elements, are extracted.

The pyrometallurgical method separates e-waste by heating elements to very high temperatures. This method requires a lot of energy.

Liquid-liquid extraction is another common method in use today. In this method, the waste is dissolved in a strong acid, and then a series of solvents are used to extract the rare earths.

Uses of Regenerated Rare Earth Elements

The use of recycled rare earth elements has increased. Most rare earth elements are used in the production of catalysts and magnets. Rare earth elements are critical in the production of high-performance magnets, alloys, glasses and electronics.

Prosea design and manufacture of LXC serial centrifuges extractors has laboratory scale centrifuges, pilot scale centrifuges and multistage production centrifuges.

Focus on being Continuous chemical equipment

provider.

If you want to learn more about our centrifugal extractor, mixer settler, Contact us Now