Continuous chemical equipment

provider

provider

Constantly meet customer needs and create value for customers

More Detail Inquiry NowThe centrifugal extractors is widely used in the extraction and separation of API(active pharmaceutical Ingredients) in the pharmaceutical industry . The synthesis and extraction of API are operated by centrifugal extractor, which has short stage retention time, rapid phase separation, high extraction efficiency, and saves investment costs and solvent recovery and regeneration costs.

At present, many pharmaceutical companies use centrifugal extractor solvent extraction method for reactive extraction of intermediates and water washing operations when conducting organic synthesis of API. The production of API is a complete process, consisting of multiple sections such as fermentation - extraction - intermediate reaction - extraction - water washing - purification, etc. The centrifugal extractor is mainly used in the extraction and water washing section.

Taking cephalosporin antibiotics as an example, in the production of cefixime, firstly fermentation is carried out to obtain the mother nucleus, and corresponding intermediates are selected to react with the mother nucleus to obtain the reaction solution. Secondly suitable extractants(solvent) are selected, and the extractant(light phase) and reaction solution(heavy phase) are pumped into centrifugal extractor from different inlets according to a certain ratio. With the rotation of rotor(bowl), the two phases are quickly mixed and dispersed through the turbine disk and impeller, and the two phase liquids are fully mass transferred, to complete the mixing and mass transfer process. The mixture is then separated into two phases by the centrifugal force generated by rotation of bowl and discharged from respective outlets.. The washing section can still use centrifugal extractor to wash the extracted organic phase, remove impurities, and then continue the back extraction - washing process until the final API product is obtained.

Taking cephalosporin antibiotics as an example, in the production of cefixime, firstly fermentation is carried out to obtain the mother nucleus, and corresponding intermediates are selected to react with the mother nucleus to obtain the reaction solution. Secondly suitable extractants(solvent) are selected, and the extractant(light phase) and reaction solution(heavy phase) are pumped into centrifugal extractor from different inlets according to a certain ratio. With the rotation of rotor(bowl), the two phases are quickly mixed and dispersed through the turbine disk and impeller, and the two phase liquids are fully mass transferred, to complete the mixing and mass transfer process. The mixture is then separated into two phases by the centrifugal force generated by rotation of bowl and discharged from respective outlets.. The washing section can still use centrifugal extractor to wash the extracted organic phase, remove impurities, and then continue the back extraction - washing process until the final API product is obtained.

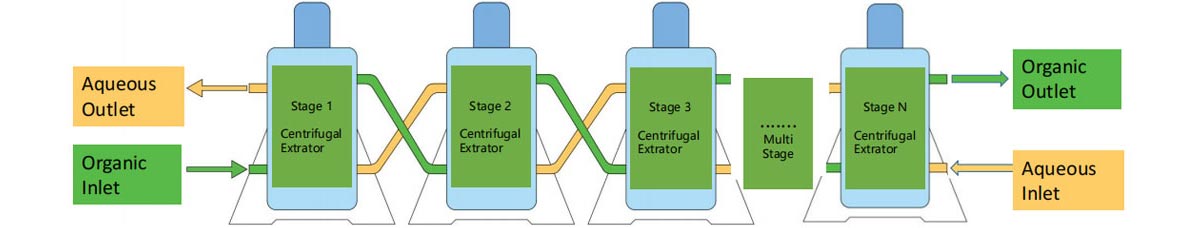

Solution:Multistage Liquid–Liquid Countercurrent Continuous Extraction

Multistage Liquid–Liquid Process Description:

1. The Multistage Liquid–Liquid Extraction process is not limited to four-stage pickling, alkali washing and water washing, and the number of countercurrent washing stages can be increased according to the actual situation;

2. The Multistage Liquid–Liquid Extraction process is suitable for separating organic mixtures immiscible with water such as acetochlor, alachlor, etc.;

3. The Multistage Liquid–Liquid Extraction process relies on centrifugal separation (hundreds to thousands of times the gravity under the same conditions), and the separation efficiency is high;

4. The Multistage Liquid–Liquid Extraction process equipment occupies a small area, low power consumption, and less residual liquid, which can realize the continuous production of the acetochlor washing

process section;

Mixer settlers are a class of Mixing Separation equipment used in the solvent extraction process. A mixer settler reactor consists of a first stage that mixes the phases together followed by a quiescent settling stage that allows the phases to separate by gravity. Mixer Settler is made by overall injection molding, without bonding or weld seams which by Prosea Tech design and manufacture.

Mixer Settler Mixing Flux:0.25-68L/H

Customized:YES

Prosea Liquid–Liquid centrifugal extractor is a new type of liquid-liquid extraction equipment developed by our company after many years of research, the Liquid–Liquid extraction equipment could realize mixed and mass transfer, reaction, extraction, washing and separation and many other functions. It has widely application in Pharmaceutica, Chemical, Food, Hydrometallurgy, Environmental and so on.

Mixing Flux:1000-350000 L/H

Model: LXC-150; LXC-250; LXC-350

Customized:YES

Focus on being Continuous chemical equipment

provider.

If you want to learn more about our centrifugal extractor, mixer settler, Contact us Now