Continuous chemical equipment

provider

provider

Constantly meet customer needs and create value for customers

More Detail Inquiry NowSalt lakes mainly refer to lakes with a salt content higher than 50g/L, which are a natural resource that integrates inorganic salts, organic matter, and biology, and only appear in specific natural and geological environments. Lithium rich salt lake is a special type of salt lake, which usually refers to the salt lake where the lithium ion concentration exceeds 24.5mg/L (Lithium chloride 150mg/L).

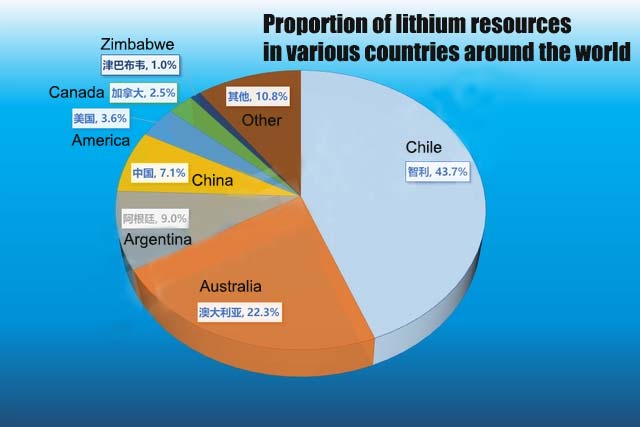

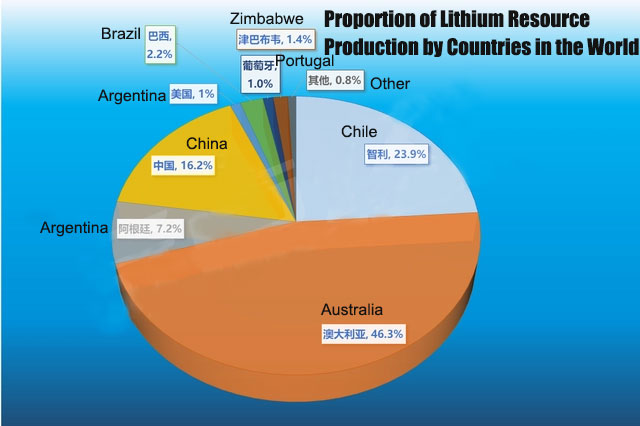

There are three main forms of lithium resources: salt lake brine lithium mine in the closed basin, Pegmatite type hard rock lithium mine, and Sedimentary rock type clay lithium mine. Among them, salt lake brine lithium mine accounts for 62.6% of the global total lithium resources, which is the most common form of lithium resources, but its development degree is far lower than mine lithium. For example, almost all lithium resources in Australia exist in the form of ores, accounting for 22.3% of global lithium resources but contributing nearly half of global production.

Separating lithium and magnesium ions from salt lake brine is the key to lithium extraction technology in salt lakes Due to their similar ionic hydration radii and chemical properties, it is difficult to separate them.

Precipitation method

The advantage lies in being able to fully utilize the geographical conditions of Tibet, such as sufficient sunlight, large temperature difference between day and night, and the presence of clay layers suitable for constructing salt fields. Solar energy and inexpensive precipitation reagents have also reduced the cost of developing lithium resources to a certain extent. The biggest drawback of this method is that the evaporation precipitation process takes a long time and takes 12-24 months to complete the extraction.

Adsorption method

Capture lithium ions through highly lithium ion selective adsorbents, and then extract lithium ions using eluents to achieve the separation of lithium ions from other impurity ions. The adsorption method for lithium extraction has high production efficiency, no environmental pollution, and a mature and reliable process. The disadvantage is that there are certain limitations in the use of carbonated salt lakes.

Electrodialysis method

The application in lithium extraction from high magnesium lithium ratio salt lake brine is of great significance. The pure physical operation of Electrodialysis to separate magnesium ion and lithium ion is simple and does not pollute the environment. The drawback is that the pre-treatment system and machine maintenance in the early stage of the electrolysis method have increased the cost of lithium extraction.

Nanofiltration method

Magnesium lithium separation is carried out through nanofiltration membranes. For salt lakes with high magnesium lithium ratios, although nanofiltration membranes can significantly reduce their magnesium lithium ratio, they cannot completely separate magnesium lithium, so they are often used in conjunction with electrodialysis. The lithium extraction process using nanofiltration is simple and low in energy consumption, but due to membrane fouling, the separation performance of the nanofiltration membrane will significantly decrease after long-term use.

Extraction method

The process of obtaining a pure lithium solution through extraction and reverse extraction using an organic solvent that is not miscible with brine and has a density not less than water. This method has low production cost and high lithium extraction efficiency, and is suitable for lithium extraction from salt lake brine with high magnesium lithium ratio.

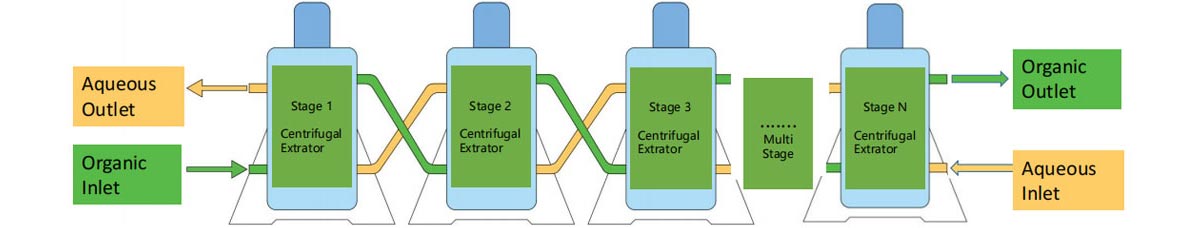

Solution:Multistage Liquid–Liquid Countercurrent Continuous Extraction

Multistage Liquid–Liquid Process Description:

1. The Multistage Liquid–Liquid Extraction process is not limited to four-stage pickling, alkali washing and water washing, and the number of countercurrent washing stages can be increased according to the actual situation;

2. The Multistage Liquid–Liquid Extraction process is suitable for separating organic mixtures immiscible with water such as acetochlor, alachlor, etc.;

3. The Multistage Liquid–Liquid Extraction process relies on centrifugal separation (hundreds to thousands of times the gravity under the same conditions), and the separation efficiency is high;

4. The Multistage Liquid–Liquid Extraction process equipment occupies a small area, low power consumption, and less residual liquid, which can realize the continuous production of the acetochlor washing

process section;

Mixer settlers are a class of Mixing Separation equipment used in the solvent extraction process. A mixer settler reactor consists of a first stage that mixes the phases together followed by a quiescent settling stage that allows the phases to separate by gravity. Mixer Settler is made by overall injection molding, without bonding or weld seams which by Prosea Tech design and manufacture.

Mixer Settler Mixing Flux:0.25-68L/H

Customized:YES

Prosea Liquid–Liquid centrifugal extractor is a new type of liquid-liquid extraction equipment developed by our company after many years of research, the Liquid–Liquid extraction equipment could realize mixed and mass transfer, reaction, extraction, washing and separation and many other functions. It has widely application in Pharmaceutica, Chemical, Food, Hydrometallurgy, Environmental and so on.

Mixing Flux:1000-350000 L/H

Model: LXC-150; LXC-250; LXC-350

Customized:YES

Focus on being Continuous chemical equipment

provider.

If you want to learn more about our centrifugal extractor, mixer settler, Contact us Now